News

News

- what kind of polaycrylamide we can use for sand washing?

- how does polyamine work in water treatment and mining ?

- Is the zetag 4100 DK a kind of cationic or anionic polyacrylamide?

- what is application of polyacrylamide used for red mud in aluminum plant?

- How does amphoteric polyacrylamide works?

- whats is main applications of amphoteric polyacrylamide?

- what is main applications of nonionic flocculant?

- what is application of polyacrylamide?How is the product classified?what is applications ?

- What are the production processes of polyacrylamide? What are their own characteristics?

- what is PHPA polymer and what is the main applicaitons in oilfeild?

About Polyacrylamide

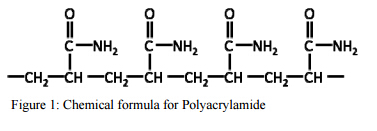

Polyacrylamide (“PAM”) is a water-soluble polymer formed from acrylamide (a compound with the molecular formula C3H5NO) subunits. PAM is most often used to increase the viscosity of water (creating a thicker solution) or to encourage flocculation of particles present in water. PAM is a synthetic chemical that can be tailored to fit a broad range of applications.

Polyacrylamide and Wastewater Treatment

One of the largest uses for PAM is to flocculate or coagulate solids in a liquid, such as in the wastewater treatment industry. PAM can be applied to various types of wastewater. The introduction of PAM as a chemical flocculating agent to wastewater causes suspended particles in wastewater to aggregate, forming what is known as a floc. In addition, PAM products react with water to form insoluble hydroxides, which upon precipitating, link together to form meshes, physically trapping small particles into a larger floc. In simple terms, PAM makes the fine solids in treated water adhere to one another until they become big enough to settle out or be captured by filters to make sewage sludge. In either case, the floc can be filtered or removed more easily.

In municipal wastewater treatment, PAM can be used in all solid-liquid separation processes including primary sewage treatment, activated sludge treatment and digested sludge treatment. In industrial wastewater treatment, the polymers and coagulants are used extensively for a wide variety of industrial processes involving paper, petrochemical, electroplating, textiles, oilfield chemical food, pharmaceutical, leather, breweries wineries, and slaughterhouses.

.jpg)

Polyacrylamide can also used to treat water from mineral mining processes, including production of coal, lead, dioxide, titanium, gold, zinc, iron, sand, phosphoric acid, silver, nickel, copper, steel, gravel, alumina uranium as well as potash processing.

Different types of wastewater require different wastewater treatment products, including different variances of PAM. The wastewater treatment product most effective in treating a particular wastewater will depend on, amongst other factors, the acids, chemicals and pollutants found in the wastewater, as well as the charge of the wastewater.

Polyacrylamide and Enhanced Oil Recovery

Another common use of polyacrylamide is in subsurface applications such as enhanced oil recovery, where high viscosity aqueous solutions can be injected to improve the economics of conventional water flooding.

For oil extraction applications, PAM is used to increase the viscosity of water to improve the effectiveness of the water flooding process. In other words, the PAM-injected solution assists in sweeping (or pushing) oil locked in a reservoir towards a production pump. The result is improved volumetric sweep efficiency – more oil is produced for a given volume of water injected into the well.

.jpg)

Historically, PAM oilfield projects primarily used PAM supplied as a solid powder. This powder is then hydrated to form an aqueous solution. More conveniently, most PAM oilfield projects now use PAM supplied in emulsion form as liquids, offering a more efficient and faster way to get the PAM into the aqueous solution.

Due largely to early adoption, Chinese PAM producers are the worldwide technological leaders with respect to the chemical compound’s usage in enhanced oil recovery. Not surprisingly, Chinese demand accounts for most of the world's consumption in this application.

Other Common Applications

· Papermaking · Ore processing · Erosion control

· Potable water treatment · Textiles manufacturing · Food additives

Raw Material Availability

The main raw material used to produce PAM is acrylamide, which is a water-soluble monomer. Availability of acrylamide is widespread globally, with manufacturers locating world-scale production facilities closer to the sites of consumption and exploiting lower-cost production locations. Most of the world's acrylamide capacity is in the United States, Western Europe, Japan and China.

Skype ID: chemicalskai