News

News

- what kind of polaycrylamide we can use for sand washing?

- how does polyamine work in water treatment and mining ?

- Is the zetag 4100 DK a kind of cationic or anionic polyacrylamide?

- what is application of polyacrylamide used for red mud in aluminum plant?

- How does amphoteric polyacrylamide works?

- whats is main applications of amphoteric polyacrylamide?

- what is main applications of nonionic flocculant?

- what is application of polyacrylamide?How is the product classified?what is applications ?

- What are the production processes of polyacrylamide? What are their own characteristics?

- what is PHPA polymer and what is the main applicaitons in oilfeild?

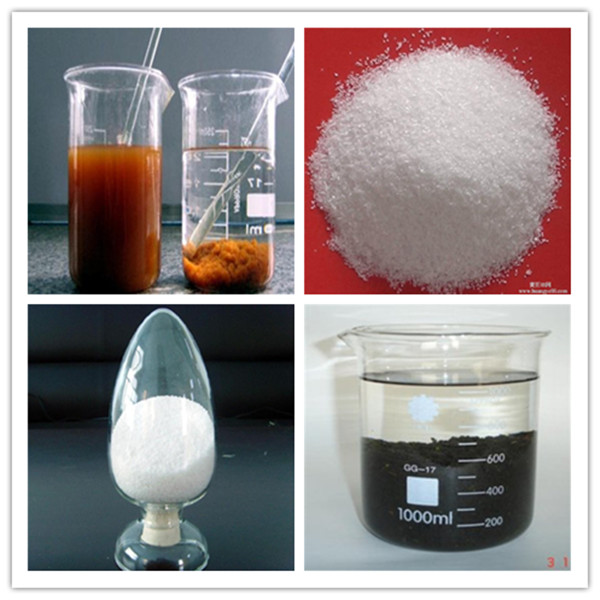

Polyacrylamide series products are water-soluble linearity high polymers. It is almost insoluble in benzene, aether, lapin and acetone and other common organic solvent and soluble easily in water. With flocculability, thickening, shear performance, resistance-diminishing performance and dispersivity, it is widely used in oil extraction, mineral separation, coal washing, metallurgy, chemical industry, papermaking, spinning, sugar manufacturing, medicine, environmental protection, building materials and agriculture industries.

Amphoteric PAM is ( the rise in the 1980s of fine chemicals ) currently the largest amount of water-soluble polymer flocculants, it is environmentally friendly - occupy a major position in sewage treatment , which involves the production of human life in many aspects , including petrochemicals Precisely because of excellent polyacrylamide , steel, power plants, paper, construction , mining , pharmaceutical , printing, and other fields, and as drilling mud regulator, displacing agent and paper usage for retention agents are very great , performance is gradually replace traditional chemicals , so usage is growing rapidly .

However, in all areas, the situation is complex, and its products will display their lack of a single species. Thus came into being zwitterion, it is for different situations. Add certain chemicals to make up for certain deficiencies, thereby increasing the effectiveness of flocculation - produced a synergistic effect, the current zwitterion mainly used in the following areas!

A : Sewage treatment : By linking the bridge , increasing alum , this more efficient than single-use aluminum chloride to a class of chemicals . Not only is there such a zwitterion performance, it also increases the hydrophobic properties of alum to make it easy to precipitate or easily adsorbed bubbles float to reduce the amount of sludge volume.

II: Sludge treatment : sludge dewatering is generally used usually cationic PAM, can be regarded as a water- clay material , the water content of more than 95% ( typically 98-99 % ) , as described above , the zwitterion and cationic stronger flocculants dewatering capacity .

III: the role of a retention aid: In papermaking, the wet pulp as the water must be filtered Internet leaving paper fibers and fillers, the process is similar to the principle of treatment of sewage sludge, which will be beneficial to add the product to help filter aid stay. Experience has shown that: For the type of paper, calculated on dry pulp, adding 0.1-3 % 2-8 % polyacrylamide to increase paper production by reducing the loss of fillers and short fibers and also reduce the processing load on the subsequent waste water. However, this effect is too strong , the paper fibers are uneven distribution of a cluster , the dry strength of the paper will affect zwitterion fiber can be distributed more uniformly in the flocculation of leaving the dry strength of short fiber reinforced display process.

Polyacrylamide containing not more than 0.2 percent of acrylamide monomer may be safely used as a film former in the imprinting of soft-shell gelatin capsules when the amount used is not in excess of the minimum required to produce the intended effect

Canonize monodisperse composite particles of polyacrylamide (PAM) and poly (acrylamide-co-2-acrylamido-2-methyl-1-propanesulfonic acid)-silica [Poly (AM-co-AMPSA)-SiO2] were prepared by water-in-oil in situ micro emulsion polymerization without surface treatment of silica. The synthesized composite particles were produced with controllable sizes ranging from 44 to 77 nm in diameter. Presence of silica filler in the nonreactors facilitates the formation of well-defined discrete particles. The prepared Nan composites were characterized by dynamic light scattering, transmission electron microscope, Fourier transform infrared spectrophotometer, thermo gravimetric analyzer, differential scanning calorimeter, scanning electron microscope and X-ray diffraction. The spectroscopic result shows strong interactions of silica nanoparticles with euphonic groups of 2-acrylamido-2-methyl-1-propanesulfonic acid (AMPSA). The onset degradation temperature is increased from 227 to 262 °C in copolymer–silica composite as compared to polyacrylamide–silica (PAM–SiO2) which indicates improved thermal stability. The shifting of glass transition temperature from 194 to 203 °C in copolymer composite mangles further confirms the existence of strong interactions of silica filler with poly(acrylamide-co-2-acrylamido-2-methyl-1-propanesulfonic acid) [Poly(AM-co-AMPSA)] chains. Also the chemical composition of polymeric chains and the affinity of polymer chains and silica influenced the morphology of mangles.